Understanding the Differences Between EVA and TPE

Introduction

Materials play a crucial role in product design and manufacturing, influencing factors such as durability, flexibility, and cost. Two commonly used materials in various industries are Ethylene Vinyl Acetate (EVA) and Thermoplastic Elastomer (TPE). While both materials offer unique benefits, they differ significantly in composition, properties, and applications.

Composition and Structure

EVA (Ethylene Vinyl Acetate) is a copolymer composed of ethylene and vinyl acetate, with its flexibility and softness increasing as the vinyl acetate content rises. Known for its lightweight and shock-absorbing properties, EVA features a closed-cell foam structure that also provides water resistance. However, it lacks the elasticity which may experience permanent deformation under sustained pressure.

TPE (Thermoplastic Elastomer), on the other hand, is a class of materials that blend the characteristics of thermoplastics and elastomers. It has rigid thermoplastic segments for durability and soft elastomeric segments for flexibility. Unlike EVA, TPE can stretch and return to its original form without losing shape. Additionally, it is recyclable, as it can be melted and reshaped multiple times.

.jpg)

EVA and TPE differ significantly in composition, properties, and applications

Physical Properties Comparison

|

Property |

EVA |

TPE |

|

Density |

0.93 - 0.98 g/cm³ |

0.89 - 1.20 g/cm³ |

|

Hardness |

Shore A 25-90 |

Shore A 5-90 |

|

Elasticity |

Moderate |

High |

|

Shock Absorption |

Excellent |

Good |

|

Softening Temperature |

Up to 80°C |

Up to 200°C |

|

UV Resistance |

Good |

Excellent |

|

Chemical Resistance |

Limited |

High |

|

Recyclability |

Limited |

High |

Applications Comparison

|

Application Area |

EVA Applications |

TPE Applications |

|

Footwear |

Insoles, midsoles, flip-flops, running shoes |

Flexible soles, shoe grips, high-performance sports footwear |

|

Sports Equipment |

Padding, yoga mats, helmet liners |

Resistance bands, ergonomic grips, protective covers |

|

Packaging |

Foam inserts, insulation materials |

Seals, gaskets, food-safe packaging materials |

|

Toys & Crafts |

Soft play mats, puzzle pieces, toy components |

Soft grips, squeezable toys, flexible connectors, yoga mat |

|

Medical Devices |

Orthopedic padding, prosthetic liners |

Catheters, tubing, surgical handles, gloves |

|

Automotive |

Interior padding, shock-absorbing elements |

Seals, gaskets, flexible tubing, dashboard covers |

|

Consumer Goods |

EVA foam cases, impact-resistant accessories |

Phone cases, toothbrush grips, flexible cables |

|

Industrial Uses |

Vibration dampeners, tool grips |

Weatherproofing materials, anti-slip surfaces |

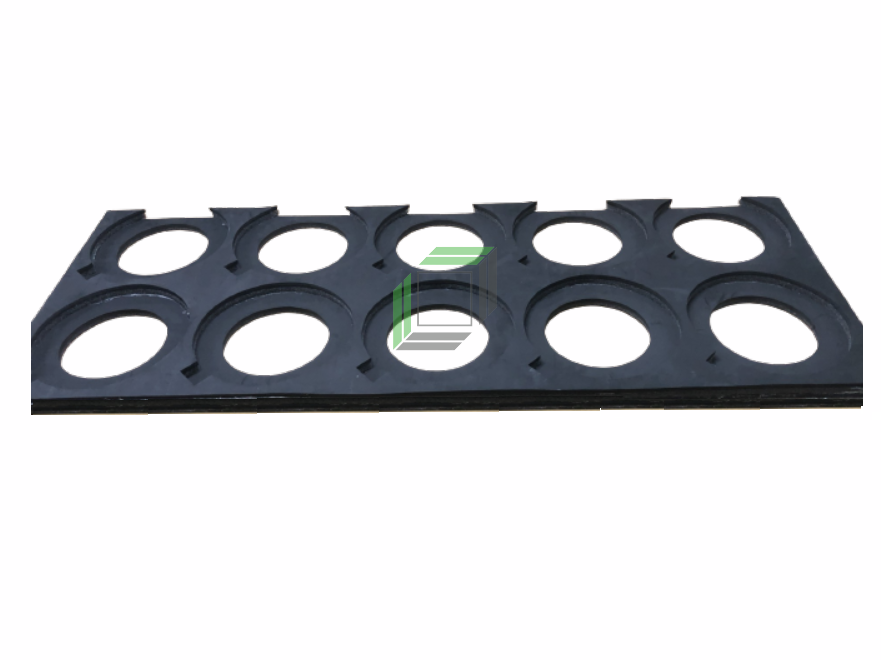

An EVA tray for electronic device transportation produce by New Edge

Combination of EVA and TPE

The combination of EVA and TPE is explored in various applications to leverage the best properties of both materials. EVA provides excellent cushioning and shock absorption, while TPE adds flexibility, resilience, and improved recyclability. By blending these materials, manufacturers can create hybrid products that optimize performance and sustainability.

Benefits of Combining EVA and TPE:

-

Enhanced Durability: Combining EVA’s toughness with TPE’s flexibility extends the lifespan of products.

-

Improved Comfort: The soft, shock-absorbing nature of EVA pairs well with the elasticity of TPE for ergonomic applications.

-

Greater Versatility: The blend can be customized for various industries, including footwear, sports equipment, and automotive components.

-

Environmental Considerations: Hybrid materials can be engineered for better recyclability, reducing waste impact.

Common Applications of EVA-TPE Blends:

-

Footwear: High-performance shoe soles and insoles that offer both comfort and flexibility.

-

Protective Gear: Helmets, knee pads, and sports padding with enhanced shock absorption and resilience.

-

Medical Equipment: Orthotic and prosthetic devices that require cushioning and elasticity.

-

Automotive Parts: Soft-touch interior components with improved impact resistance.

Environmental Impact

EVA and TPE have different environmental impacts due to their composition and recyclability.

EVA is not easily recyclable due to its cross-linked structure, and its disposal often contributes to environmental pollution. Incineration of EVA can release harmful chemicals, including volatile organic compounds (VOCs), into the atmosphere. However, recent advancements in recycling technologies have led to some progress in reprocessing EVA waste, such as mechanical and chemical recycling techniques. Additionally, some companies are developing biodegradable alternatives to EVA to minimize its environmental footprint.

TPE, being a thermoplastic material, is considered more environmentally friendly. It can be melted and reprocessed multiple times without significant degradation, making it a highly recyclable option. TPE’s ability to be reformed without chemical alteration allows manufacturers to reduce production waste and reuse scrap materials efficiently. Additionally, certain TPE formulations are designed to be biodegradable, further enhancing their sustainability profile.

A combination of EVA and TPE in children toy for school education produced by New Edge

The use of EVA-TPE blends can also contribute to reducing environmental impact. By integrating TPE’s recyclability with EVA’s cushioning properties, manufacturers can create products that are more sustainable while maintaining high performance. Efforts to develop eco-friendly TPE formulations and improve EVA recyclability continue to drive innovation in material science, aiming for more sustainable production processes across industries.

EVA-TPE Products at New Edge

New Edge provides high-quality EVA and TPE raw materials as well as customized products tailored to meet customer needs. The company specializes in manufacturing various EVA-TPE products in different sizes and shapes, including:

-

Flat Sheets: Standard EVA/TPE sheets that can be used in various industrial and consumer applications.

-

Die-Cut Shapes: Precision-cut EVA/TPE components designed for specific applications, ensuring a perfect fit.

-

Advanced CNC EVA Products: High-precision EVA/TPE parts produced using CNC technology, ideal for packaging, cushioning, and protective applications.

CNC EVA for electronic device packing produced by New Edge

With the ability to customize products based on specific customer requirements, New Edge ensures that businesses receive materials and products that meet their functional and aesthetic needs while maintaining high-quality standards.

Conclusion

Both EVA and TPE have unique properties that make them suitable for different applications. EVA excels in lightweight cushioning and shock absorption, while TPE offers superior flexibility, durability, and recyclability. Additionally, blending these materials provides a hybrid solution that enhances performance across multiple industries. The choice between these materials depends on specific application requirements, environmental considerations, and cost factors. Understanding their differences and synergies allows manufacturers and designers to make informed decisions that optimize product performance and sustainability.For more information on EVA and TPE materials or to discuss your specific product needs, contact New Edge today. Our team is ready to assist you with high-quality raw materials and customized product solutions tailored to your requirements.

P/S: New Edge News